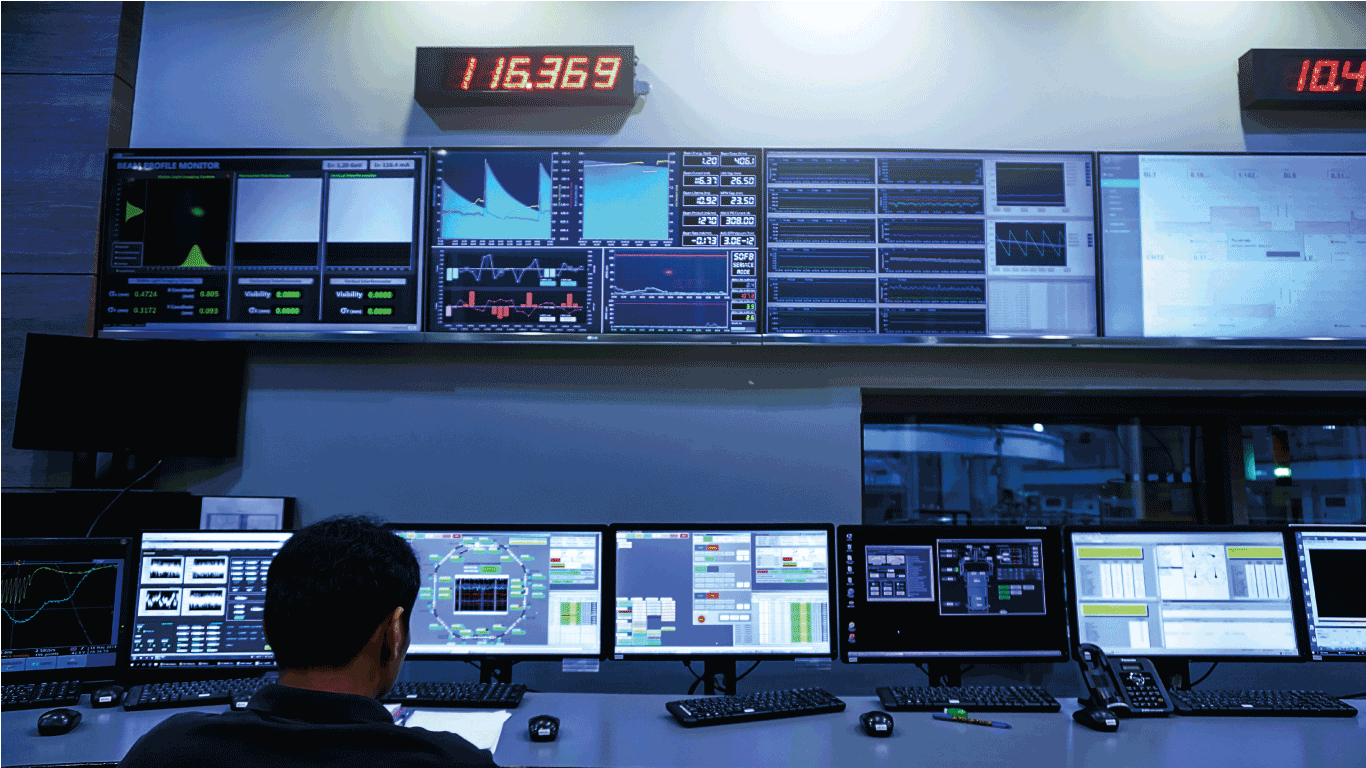

PREDICTIVE MAINTENANCE AND REMOTE DIAGNOSTICS

Predictive maintenance and remote diagnostics refer to the use of data science and proactive maintenance methods to detect various deterioration signs in your operation and possible failures to reduce downtime and cost of maintenance. The underlying architecture of predictive maintenance is the power of IoT, big data analysis, cloud computing, and dynamic case management to identify equipment vulnerability and to help devices become proactive participants in their maintenance. Data science and predictive analytics for future potential failures allow corrective and preventative maintenance to be scheduled before any failure happens. Potentially, our control and monitoring system consisting of sensors, analyzers, software, controllers on the equipment continuously monitor and record their behavior and operational status. These data are filtered and aggregated to prescribe maintenance tasks as part of dynamic cases. Maintenance tasks include predetermined repetitive process fragments and allow different categories of maintenance work to be automated, monitored, and optimized of the HVAC system.

OPERATIONAL COST REDUCTION

learn more

PREDICTIVE MAINTENANCE AND REMOTE DIAGNOSTICS

learn more

PORTFOLIO SUSTAINABILITY ASSESSMENT

learn more

FAULT DETECTION AND TROUBLESHOOTING

learn more

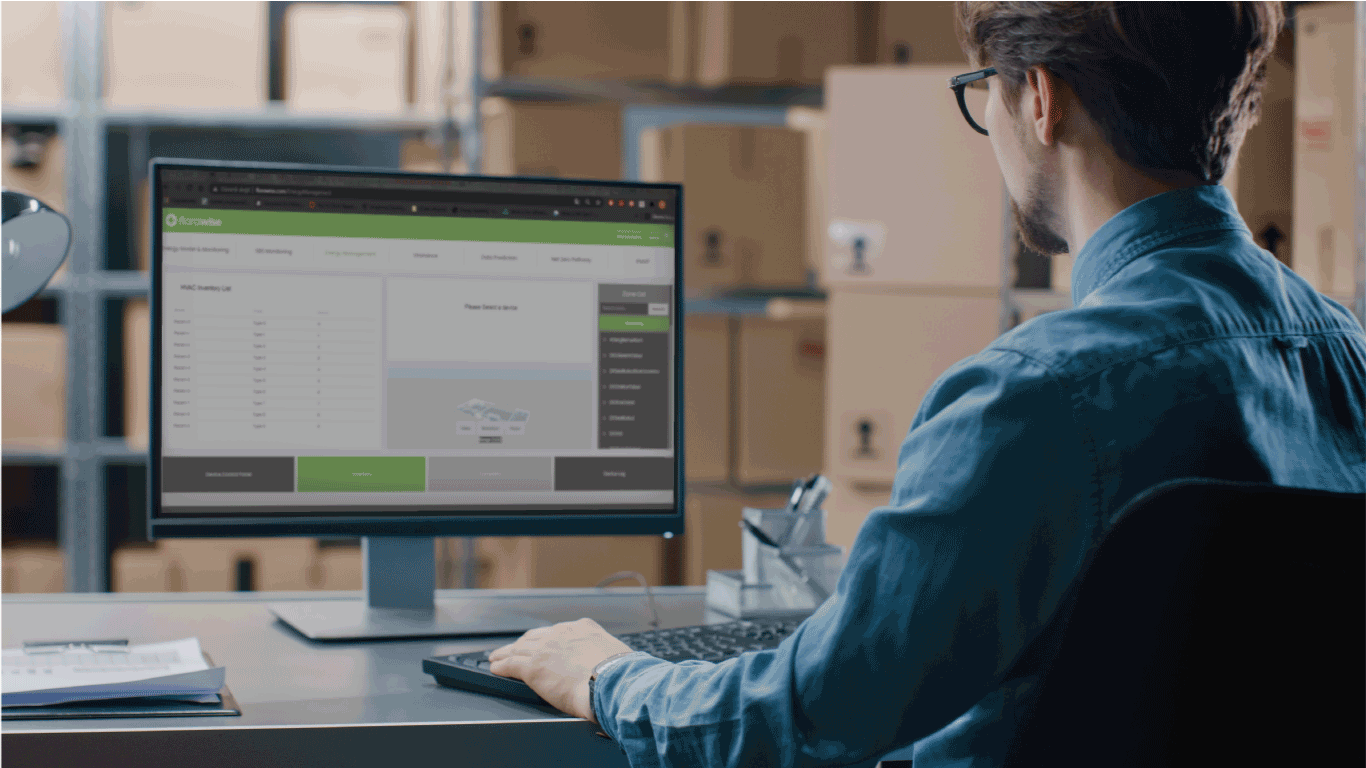

HVAC INVENTORY TRACKING

learn more